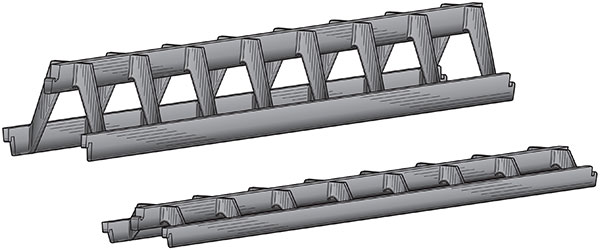

GTI Slab Bolsters Upper

All GTI Bar Supports are 100% Made in the USA

GTI provides the strongest Slab Bolster Upper available in the market. They are made from composite material and meet or exceed the strength of comparable wire supports by up to ten times. GTI offers continuous corrosion protection, both on the job-site and in concrete providing a great alternative to epoxy, stainless, and galvanized bar supports.

GTI Slab Bolster Upper easily snaps together to eliminate overlapping and the use of tie-wire, saving approximately 8% in material cost and additional labor savings.

Primary Uses:

- Top Layer Double Mat Support – Post-Tensioning, Rebar, or Wire Mesh

Sizes:

- From 1” to 2½” (in ¼” increments) x 5’ long

- Additionally, 3” and 4” x 5’ long

Features:

- Continuous runner

- Designed for maximum aggregate flow and concrete consolidation

- Snap-Locking System

- Wide stable base

Product Applications:

- DOT Department of Transportation

- PC Precast

- PT Post-Tensioned

- SOG Slab-on-Ground

- SE Slab – Elevated

- TU Tilt-Up

| SIZE | PART NO. |

|---|---|

| 1" | 260100 |

| 1 1/4" | 260125 |

| 1 1/2" | 260150 |

| 1 3/4" | 260175 |

| 2" | 260200 |

| 2 1/4" | 260225 |

| 2 1/2" | 260250 |

| 3" | 260300 |

| 4" | 260400 |

See Patents for a listing of many of the patents licensed to GTI, including patents that may cover one or more of the products identified on this page.

Notice of exclusive terms and conditions: all sales or purchases by gti respectively incorporate and adopt gti’s standard terms and conditions of sale or purchase and the specific terms (e.g. delivery, price, quantity) of each specific transaction all as set forth in the controlling purchase order.

PROPER CARE AND USAGE: Do not leave GTI Bar Supports in the sun or in bright daylight for prolonged periods of time – composites, plastics, and bags may become brittle; the material used to manufacture GTI Bar Supports is physiologically safe and resistant against all acids and alkaline solutions used in the construction industry; do not apply oils, release agents, or similar products to GTI Bar Supports; under certain conditions small rupture may occur at the surface of concrete in the vicinity of GTI Bar Supports when too much oil or release agent is used on the formed surface – further causes may be poor cleaning of the concrete surface and improper use of primer when painting; GTI Bar Supports have been used world-wide in every climatic condition without complaint.